High-Precision

Surface Cleaning.

No Damage.

No Downtime.

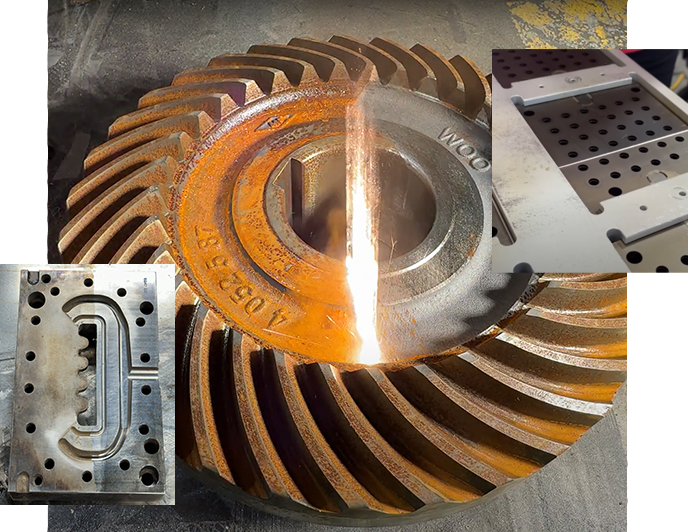

Laser cleaning offers precise control for removing rust, paint, grease, and coatings without damaging the base material. It reduces waste, improves safety, and outperforms traditional abrasive methods in both speed and efficiency.

Where Laser Cleaning

Outperforms Traditional Methods

OxideRemoval

- Cleans oxidized metal surfaces quickly

- Improves surface quality for further processing

- Essential for electronics and semiconductor manufacturing

CoatingRemoval

- Targets specific layers without damaging the substrate

- Effective on various coatings and surfaces

- Creates ideal surface for new coating adhesion

GreaseRemoval

- Vaporizes grease and oil residues

- Leaves surfaces clean and ready for use

- Ideal for industrial machinery and equipment

SurfaceDecon-tamination

- Removes hazardous materials safely

- Effective for nuclear and chemical industries

- Reduces health risks associated with contamination

NDI/NDTNon-Destructive Inspection/Testing

- Prepares surfaces for accurate inspections

- Enhances the reliability of test results

- Crucial for aerospace and automotive industries

WeldingPrep

- Cleans surfaces for optimal weld quality

- Improves weld strength and appearance

- Increases efficiency in manufacturing processes

Targeted Solutions. proven performance.

Explore What Laser Cleaning Can Do in Your Industry

Art & Heritage

Gentle, chemical-free cleaning for sculptures, monuments, and historic facades.

Questions About Your Application?

Share a few details and an expert will confirm fit, expected results, and the best path forward.