Introducing the Next Evolution in Laser Technology

Nuwave Laser is expanding beyond laser cleaning and stepping into the next era of precision manufacturing with its new line of NOVAWELD™ Laser Welding Machines. Designed with the same quality and reliability our customers expect, this new lineup brings advanced laser welding capabilities that combine power, accuracy, and ease of use.

Nuwave Laser has been trusted for high-performance laser cleaning systems that redefine efficiency and precision in surface preparation. Now, we’re taking that expertise one step further. Our new laser welding machines bring that same innovative engineering to metal joining, giving fabricators, manufacturers, and repair professionals a faster, cleaner, and more durable welding solution.

Why Laser Welding?

Traditional welding methods often come with challenges. From excess heat and material distortion to time-consuming cleanup. Laser welding changes that. By focusing intense, controlled laser energy, users can achieve stronger, cleaner, and more precise welds with minimal post-processing. NOVAWELD machines are built to simplify complex welds while delivering unmatched consistency.

What Is a Laser Welding Machine?

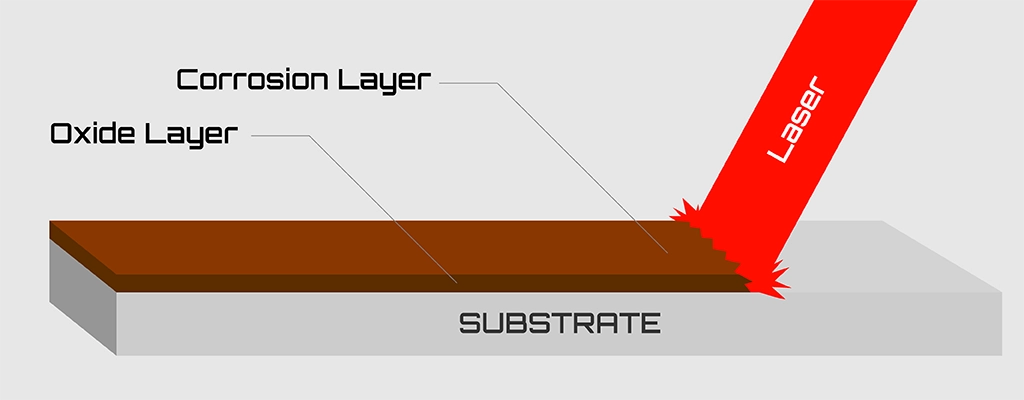

In basic terms, a laser welding machine uses a highly focused beam of light to melt and fuse materials together. Because the laser beam can be concentrated with intense power density, it creates very narrow, deep welds with minimal thermal impact on the surrounding material.

Nuwave Laser’s new handheld laser welders take precision and performance to the next level. Built on our self-developed “small core diameter” laser technology, these machines feature an advanced dual-circuit refrigerant cooling system and an integrated structural design for superior efficiency and reliability. Designed to handle a wide range of metals, including aluminum, stainless steel, carbon steel, galvanized sheet, and brass, these welders deliver high penetration, energy efficiency, and unmatched convenience. For specialized applications, custom configurations are also available, ensuring every user gets the exact performance their work demands.

What Makes Our Laser Welding Machines Stand Out?

- Integrated design of the complete set ensures higher welding efficiency, longer service life, and lower maintenance costs.

- Higher stability for around-the-clock operation

- Adopting Dual Circuit Refrigerant Direct Cooling Technology to eliminate the shortcomings of traditional air-cooled and water-cooled welders.

- The adaptive repair process package ensures life-cycle reliability.

Built on Proven Expertise

Our commitment to quality technology isn’t new, it’s what built our reputation. Just as Nuwave Laser Cleaning Machines set new standards in surface preparation, our Laser Welding Machines will redefine how industries approach joining and fabrication. Every model has been tested, refined, and engineered for reliability, ensuring that customers get the same performance and support they’ve come to expect from Nuwave.

Designed for Every Industry

Our new laser welding machine will serve a broad spectrum of industries and use-cases, including:

- Automotive & Transportation: High-volume components, battery modules, frame assemblies.

- Aerospace & Defense: Lightweight structures, fatigue-critical joints, advanced alloys.

- Electronics & Micro-fabrication: Welding very thin materials, small devices, and tight-tolerance parts.

- Jewelry, Medical, Tool & Die: Precision welds on small parts, often where appearance and strength matter.

- Repair & Refurbishment: Tooling repair, mold repair, hard-to-access joints where minimal distortion is critical.

A New Standard in Laser Welding

If you’ve been searching for “laser welding machine,” or exploring how laser welding can upgrade your fabrication workflow, now is a great time to connect with Nuwave Laser. We’ll help you evaluate fit-up requirements, materials, joint design, automation options, and ROI. We believe your next welding system should not only produce superior welds, but also do so faster, cleaner, and with less fuss.

For more information, please contact our team to speak to an expert at Nuwave Laser. We look forward to helping your fabrication process step into the future of laser welding.