LASER WELDING MACHINES

Nuwave Laser's NOVAWELD™ series is the next generation of handheld laser welding machines. These portable and powerful systems are engineered for fabricators, repair shops, and manufacturers who demand industrial-grade performance. Whether you need a precise system for smaller jobs with the NOVAWELD Core series or a dependable solution for large-scale welding jobs with the NOVAWELD Titan, Nuwave laser welding machines will get the job done.

Modern Welding for

Modern Shops

| Specifications | NXC-700 | NXC-900 | NXC-1200 | NXT-1500 | NXT-2000 |

|---|---|---|---|---|---|

| Laser Power | 700W | 900W | 1200W | 1500W | 2000W |

| Power Consumption | 2.5 kW/h | 3.25 kW/h | 3.8 kW/h | 5 kW/h | 7 kW/h |

| Fiber Core Diameter | 30 μm | 14 μm | 14 μm | ||

| Cooling | Dual-Circuit Refrigerant Direct Cooling | Dual-Circuit Refrigerant Direct Cooling | |||

| Welding Speed | 20-300 cm/min *Material Dependent | 20-300 cm/min *Material Dependent | |||

| Weld Penetration: Carbon Steel | 0-2.5 mm ≈ (0.09" ~ 3/32") | 0-3 mm ≈ (0.125" ~ 1/8") | 0-4 mm ≈ (0.156" ~ 5/32") | 0-6 mm ≈ (0.24" ~ 1/4") | 0-7 mm ≈ (0.31" ~ 5/16") |

| Weld Penetration: Stainless Steel | 0-2.5 mm ≈ (0.09" ~ 3/32") | 0-3 mm ≈ (0.125" ~ 1/8") | 0-4 mm ≈ (0.156" ~ 5/32") | 0-6 mm ≈ (0.24" ~ 1/4") | 0-7 mm ≈ (0.31" ~ 5/16") |

| Weld Penetration: Galvanized Steel | 0-2.5 mm ≈ (0.09" ~ 3/32") | 0-3 mm ≈ (0.125" ~ 1/8") | 0-4 mm ≈ (0.156" ~ 5/32") | 0-6 mm ≈ (0.24" ~ 1/4") | 0-7 mm ≈ (0.31" ~ 5/16") |

| Weld Penetration: Aluminum | 0-2 mm ≈ (0.078" ~ 5/64") | 0-2.5 mm ≈ (0.098" ~ 3/32") | 0-3.5 mm ≈ (0.137" ~ 9/64") | 0-5 mm ≈ (0.196" ~ 13/64") | 0-6 mm ≈ (0.31" ~ 5/16") |

| Weld Penetration: Brass | 0-2 mm ≈ (0.078" ~ 5/64") | 0-3 mm ≈ (0.125" ~ 1/8") | 0-4 mm ≈ (0.156" ~ 5/32") | 0-6 mm ≈ (0.236" ~ 15/64") | 0-7 mm ≈ (0.31" ~ 5/16") |

| Weld Penetration: Copper | / | 0-0.5 mm ≈ (0.019" ~1/64") | 0-1 mm ≈ (0.04" ~ 3/64") | 0-2.5 mm ≈ (0.098" ~ 6/64") | |

| Wire Diameter | 0.8 mm / 1.0 mm / 1.2 mm | 0.8 mm / 1.0 mm / 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm | 0.8 mm / 1.0 mm / 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm | ||

| Weld Modes | Spot, Continuous, Continuous Spot, Pulse | Spot, Continuous, Continuous Spot, Pulse | |||

| Preset Programs | 16 | 24 | 31 | 46 | |

| Custom Programs | Up to 20 user-defined | Up to 20 user-defined | |||

| Torch | .86 lbs (390 grams) | 180° Grip Angle | 50°-60° Wire Feed Angle | .86 lbs (390 grams) | 180° Grip Angle | 50°-60° Wire Feed Angle | |||

| Working Temperature | -4°F - 140°F (-20°C - 60°C) | -4°F - 140°F (-20°C - 60°C) | |||

| Working Humidity | 0-90% | 0-90% | |||

Explore Laser Welding Machine Options

Choose a Category to See Models, Specs,

and Use Cases.

Designed For Flexible Performance on a Broad Range of Metal Materials.

- Aluminum

- Stainless Steel

- Carbon Steel

- Galvanized Steel

- Brass & Copper

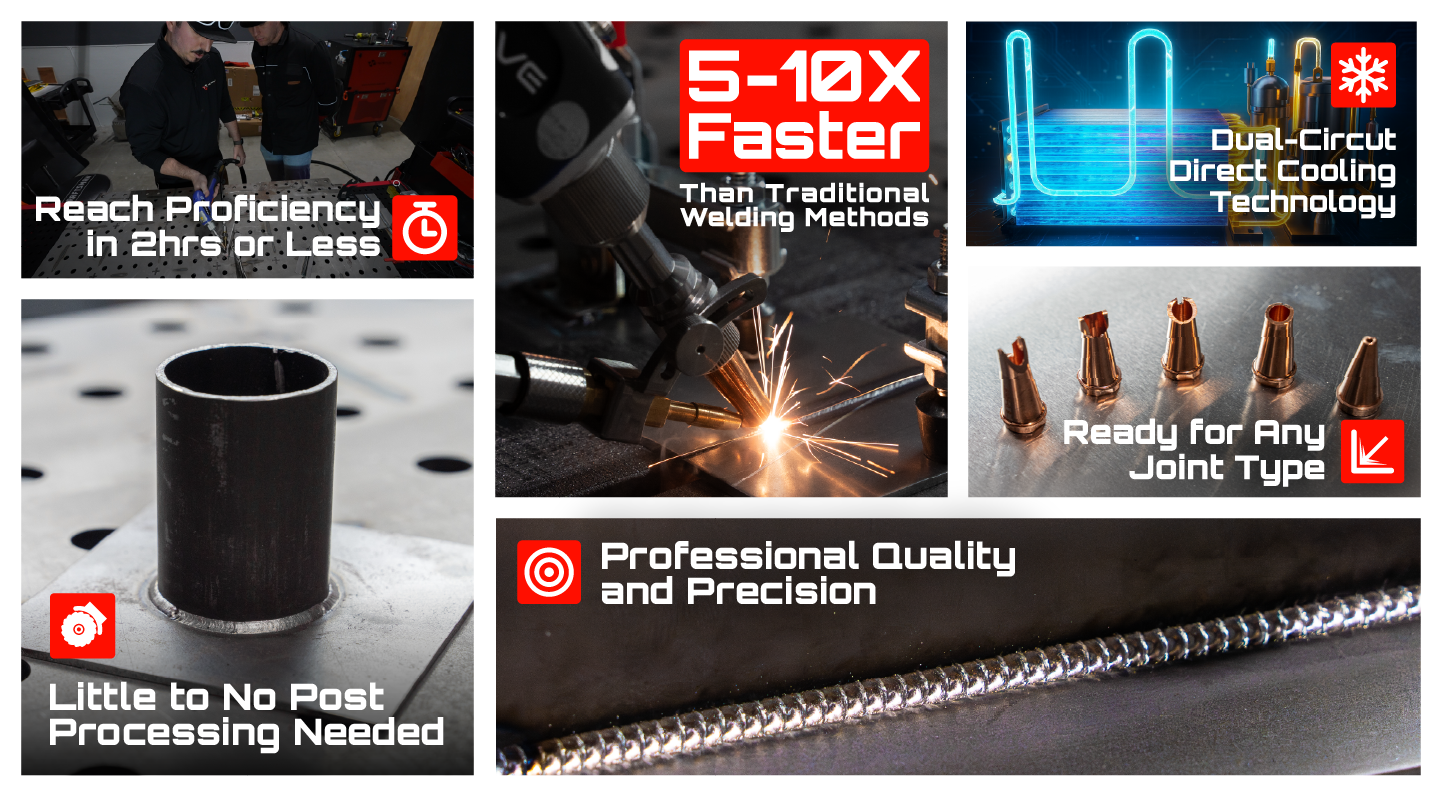

Key Advantages

- Advanced Dual-Circuit Cooling System: Engineered for continuous operation in demanding environments, the dual-circuit refrigerant cooling system maintains stable performance from –20°C to 60°C—delivering industrial-grade reliability where air-cooled units fall short.

- Ergonomic, Lightweight Torch: Weighing just 390 g, the ergonomic NOVAWELD torch reduces fatigue and provides steady, precise control during extended use.

- Deep Weld Strength, Minimal Heat Impact: A fine, concentrated beam produces deep weld penetration with a minimal heat-affected zone—reducing distortion while maintaining superior joint strength.

Not Sure Which System You Need?

We’ll help you compare your options and choose the laser welding machine that aligns with your workload, materials, and production goals.