Manufacturing

Restore Performance Without Wear

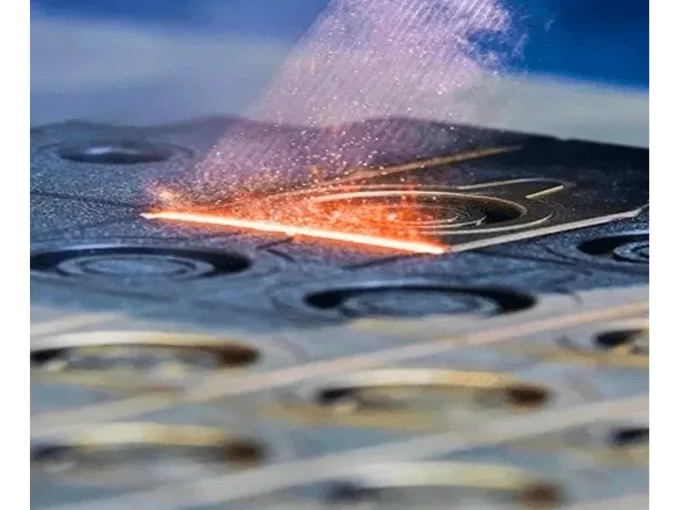

Keeping a manufacturing plant operational can be a challenging task, and equipment maintenance is crucial to ensure efficient and uninterrupted production. Our laser cleaning technology is capable of degreasing and eradicating erosion, wear marks, and grime build-up from equipment, helping our customers to maintain their machinery in top condition.

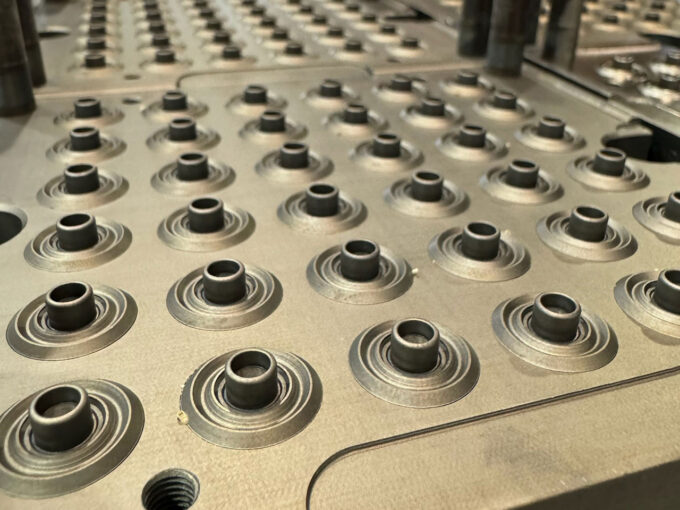

In addition, we can effectively clean molds, removing any residue without damaging polished surfaces, leaving the molds intact. Our process is fast, effective, and non-damaging to the original surface.

Keep the Line Moving with Portable Laser Cleaning

Our portable laser cleaning technology allows us to move efficiently from machine to machine, without affecting the workflow of the entire operation. Furthermore, it can prepare surfaces for welding and clean up old weld joints that may be failing, making it easier to identify cracks and re-weld without the need for manual sanding.

- Laser cleaning of equipment and machinery

- Degreasing and cleaning to remove erosion and grime build-up

- Laser cleaning of molds without damaging polished surfaces

- Laser cleaning for welding preparation and post-cleaning

- Laser cleaning of stainless-steel filters and anilox rollers

Continue the Journey

Learn the Method or See Pulse Wave Machines

Modernize Your Manufacturing Prep

Remove grime and scale on equipment without shutting down lines. Consistent, repeatable results shift after shift.