Tired of dealing with caustic chemicals every time you need to remove rust or stains from a surface? It’s time for an upgrade.

Industrial laser cleaning machines can be an invaluable addition to your company. They blast away grime and ruse with a beam of light.

You can use the beam to clean a wide range of equipment and surfaces. Ready to start cleaning? Not so fast. You’ve got to figure out which system will be the best fit for your business.

There are two main types of machines: pulse and continuous wave. Here’s a look at each piece of equipment and the unique advantages they provide.

What’s a Pulse Laser Cleaning Machine?

Pulse lasers operate by emitting short, high-intensity bursts of energy. These pulses typically last for a few nanoseconds or microseconds. The highly concentrated beam can effectively vaporize contaminants without causing damage to the underlying material.

Pulse laser cleaning machines use the technology to facilitate the precise removal of debris and contaminants. Your team members can work in tight spaces and remove rust or other material from machinery without damaging the underlying surface (the substrate).

Key Benefits of Pulse Lasers

You can use a pulse laser to clean surfaces with surgical precision. The quick burst of energy helps prevent overcleaning and allows you to target specific areas of concern on a piece of equipment or surface.

Since the machine releases energy in short bursts, it emits much less heat and operates with greater electrical efficiency. Pulse lasers are cost-effective to operate and maintain, making them an excellent long-term investment.

Users appreciate the versatility of pulse machines. They are used in a wide range of industries, including the automotive and aerospace fields.

What’s a Continuous Wave Laser Cleaning Machine?

Continuous wave laser cleaning machines emit a steady beam of energy rather than short pulses. They are more powerful and can complete jobs much faster due to the continuous operation. However, it’s important to use that power wisely.

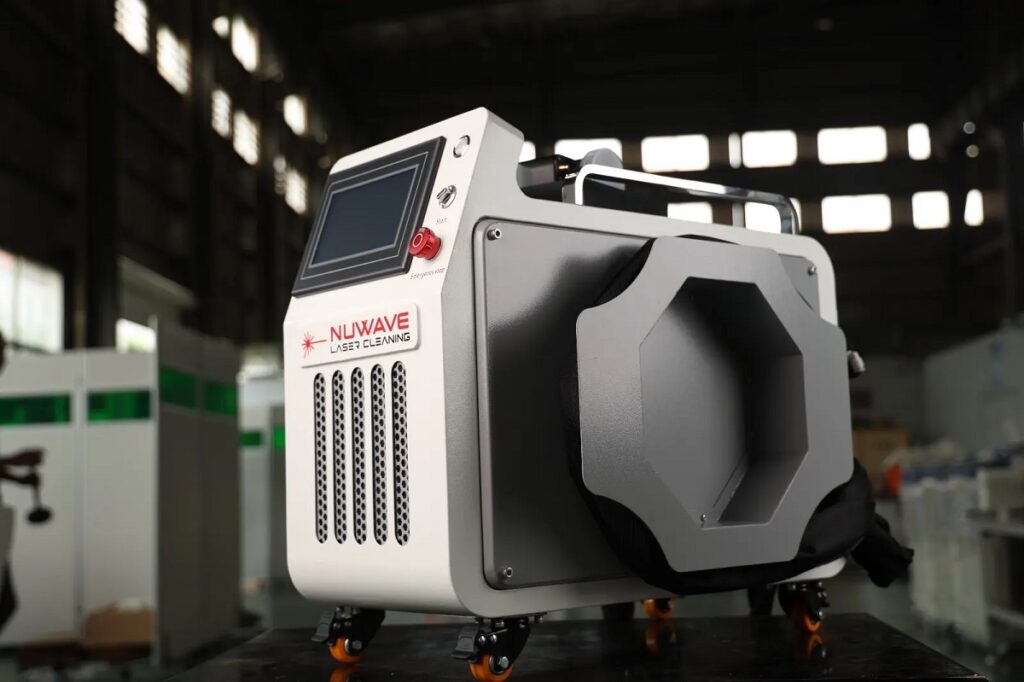

Continuous wave laser machines can provide too much penetration and remove surface material too quickly if you are not careful during operation. Fortunately, high-end options such as those provided by Nuwave have user-friendly controls that allow your team to adjust power settings with precision.

Advantages of Continuous Wave Laser Cleaning Machines

Continuous wave devices are incredibly efficient. Your team can tackle large projects with ease, making these machines ideal for industrial-scale operations. They are especially effective for removing thicker coatings and contaminants.

The continuous energy output allows CW lasers to work efficiently on tough materials like metals and thick protective coatings. You can use them to prep surfaces for reconditioning.

High-end machines also include user-friendly interfaces and provide a high level of customizability. Your team will be able to adjust the power output and other criteria for a precise cleaning experience.

Which Machine Should You Choose?

Both devices are great options for removing various stains and contaminants. However, each has a slightly different purpose. Pulse laser machines are best suited for tasks like:

- Gear surface rust removals

- Weld seam cleaning

- Oil cleaning

Continuous wave machines are a better fit when you need to perform:

- Derusting

- Plate derusting

- Steel stripping

Continuous wave devices are more powerful and penetrate to a greater depth, allowing you to tackle tougher jobs. Pulse machines are ideal for removing thin layers of rust and contaminants on a small scale.

Ready to Order Yours? We’ve Got You Covered

Need a hand choosing the right laser cleaning machines for your business? Contact Nuwave and speak with an expert.