The Challenge of Rust

What if you could erase rust in seconds without chemicals, abrasives, or damage to the base metal? From automotive frames to aerospace components and heavy industrial machinery, rust silently threatens performance, safety, and longevity. Traditional rust removal methods, such as mechanical abrasion, chemical treatments, and blasting, often carry drawbacks: they can damage the base material, produce hazardous waste, or require extensive labor and masking. That’s where laser rust removal comes into play. At Nuwave Laser, we believe laser-based approaches represent the next generation of surface restoration, combining precision, safety, and efficiency.

What Is Laser Rust Removal?

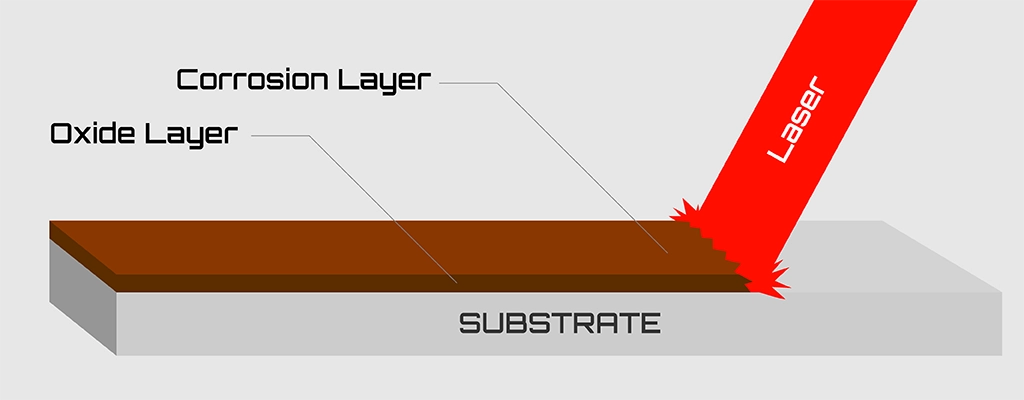

Laser rust removal is a non-contact cleaning technique that uses focused laser energy to vaporize or dislodge oxide and corrosion layers from metal surfaces while leaving the base metal intact. The laser’s wavelength and pulse characteristics can be tuned so that it targets the rust (or oxide) preferentially, avoiding damage to the underlying substrate. And because the process is so controllable, you can remove rust from complex geometries, tight edges, or delicate parts that might be damaged by abrasive or chemical methods.

Whether you are doing light restoration on small parts or large-scale industrial surface prep, Nuwave’s laser machines are engineered to deliver consistent performance across a spectrum of power levels. Our U.S.-based support team ensures your laser systems stay optimized, because uptime is critical in any production environment.

Why Use a Laser Cleaning Machine for Rust Removal?

Precision and Selectivity

Precision and Selectivity

One of the biggest advantages of a laser rust removal system is precision. Since the laser can be controlled with fine resolution, you can target rust and corrosion layers without harming the base metal. Unlike sandblasting or abrasive methods (which may overshoot or gouge), a rust removal laser is selective and minimally invasive.

Minimal Secondary Waste

Minimal Secondary Waste

Many traditional rust removal methods create residues like abrasive grit, chemical runoff, or dust, which require containment. Laser cleaning largely avoids these issues. The removed material is often captured via extraction systems or vacuum, greatly reducing cleanup and disposal costs.

Safe and Environmentally Friendly

Safe and Environmentally Friendly

Rust removal lasers eliminate the need for harsh acids, solvents, or corrosive chemicals, making the process safer for operators and the environment. Many industries have strict regulations around chemical disposal; laser rust removal helps you stay compliant while maintaining high standards of cleanliness.

Versatility Across Substrates

Versatility Across Substrates

Whether the base metal is steel, stainless steel, aluminum, or more exotic alloys, a properly tuned laser system can clean rust or oxide layers from many materials. Because the laser doesn’t physically contact the surface, it can handle intricate shapes, weld seams, corners, and internal recesses more easily than mechanical tools.

Common Applications of Laser Rust Removal

Industrial Equipment: Large components in factories, turbines, molds, or construction equipment are often subject to corrosion in harsh environments. Laser rust removal offers a way to restore these parts without disassembly or exposure to harsh chemicals.

Automotive: In the automotive sector, parts like frames, brackets, rails, or underbody components may accumulate rust over time. With a rust removal laser, these parts can be cleaned precisely without compromising tolerances or coatings.

Aerospace: For critical components in aerospace, maintaining the integrity of alloys and ensuring low surface roughness is paramount. Laser rust removal can clean corrosion from landing gear, structural parts, or brackets with minimal risk to the underlying material.

Choosing the Right Laser System for Rust Removal

To get effective results with a rust removal laser, you must consider several key factors:

- Power & Peak Intensity: Higher wattage, in the 2000-3000 watt range, may be necessary for efficient cleaning of thick corrosion or large surfaces.

- Pulse vs. Continuous Wave: While pulsed lasers excel at precision cleaning on delicate materials, continuous wave (CW) systems are generally preferred for rust removal. CW lasers provide steady, uniform energy for efficient oxide breakdown across larger surfaces.

- Beam Delivery & Scanning: The method of directing the laser affects reach, speed, and access to complex geometries.

- Cooling & Duty Cycle: For industrial throughput, you need a system designed for continuous or high-duty-cycle use without overheating or failure.

- Extraction & Filtration: Rust removal generates particulates and vaporized oxides. Proper extraction and filtration systems are critical for operator safety and maintaining a clean work environment.

- Operator Safety & Controls: Interlocks, shielding, safety enclosures, and software control all factor into a reliable, safe system.

At NuWave Laser, our laser cleaning machines combine high power, precision scanning, and advanced cooling to remove corrosion quickly and cleanly across a wide range of metals. Each machine is built for consistent performance in demanding industrial environments, supported by U.S.-based service to keep your operation running smoothly.

Overcoming Misconceptions

Some may assume that a rust removal laser is prohibitively expensive or too exotic for everyday use. In reality, the long-term cost savings from reduced labor, consumables, waste handling, and rework often justify the investment. Others might believe laser cleaning machines are too risky or damaging. However, our systems incorporate safety interlocks and modes to prevent harm to the substrate or operator.

Another misconception is that laser cleaners are only for small parts. While some desktop models exist, industrial-scale laser cleaning systems (100s to 1,000s of watts) can handle larger assemblies and heavy-duty components. At Nuwave Laser, our scalable lineup makes laser rust removal accessible across varied sizes and industries.

Best Practices & Tips for Effective Laser Rust Removal

- Do a small test first. Always run a test on a representative piece to confirm optimal parameters before continuing to a full-scale cleaning.

- Adjust in layers. Remove rust gradually rather than blasting at maximum power. This avoids overshooting into the base material.

- Maintain your focus and positioning. Ensure consistent distance and angle to prevent hot spots or uneven cleaning.

- Use proper ventilation. Always operate with appropriate fume extraction or vacuum to capture particulate and protect the operator.

- Monitor heat build-up. Especially for thin parts, avoid prolonged stationary exposure to prevent warping or discoloration.

- Keep optics clean. Dust or contamination on optics can reduce laser effectiveness.

Partner with Nuwave Laser for Expert Rust Removal

In industries where surface integrity, turnaround time, and contamination control matter, our laser rust removal technologies offer a compelling alternative to traditional methods. The precision, safety, efficiency, and minimal waste profile make laser cleaning a forward-looking investment.

If you’re evaluating ways to modernize your rust removal processes or need help selecting the right system, Nuwave Laser is ready to help. Contact us to test your parts in our lab, explore system options, or schedule a proof-of-concept demo.