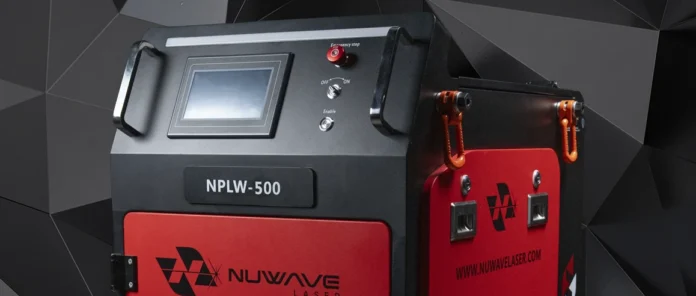

LASER CLEANING MACHINES

Laser Ablation, also known as laser cleaning, removes rust, paint, and surface contaminants with precision and ease. Nuwave’s Laser Cleaning Machines deliver powerful, eco-friendly surface preparation for metals, molds, and industrial components.

Explore Laser Cleaning Machine Options

Choose a Category to See Models, Specs,

and Use Cases.

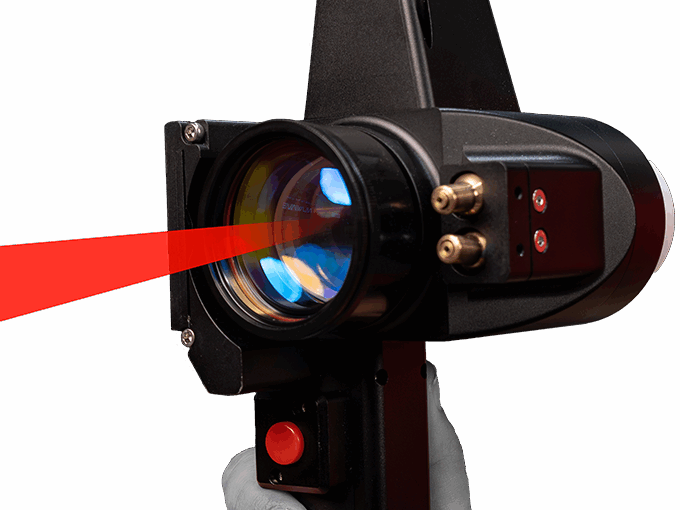

What is Laser Cleaning and How Does It Work?

- A laser device emits high-frequency pulses of light.

- The light energy is absorbed by surface contaminants (e.g., rust, paint, oxides).

- The contaminants rapidly heat up and vaporize.

- The underlying material remains unaffected due to its different absorption characteristics.

Key Advantages

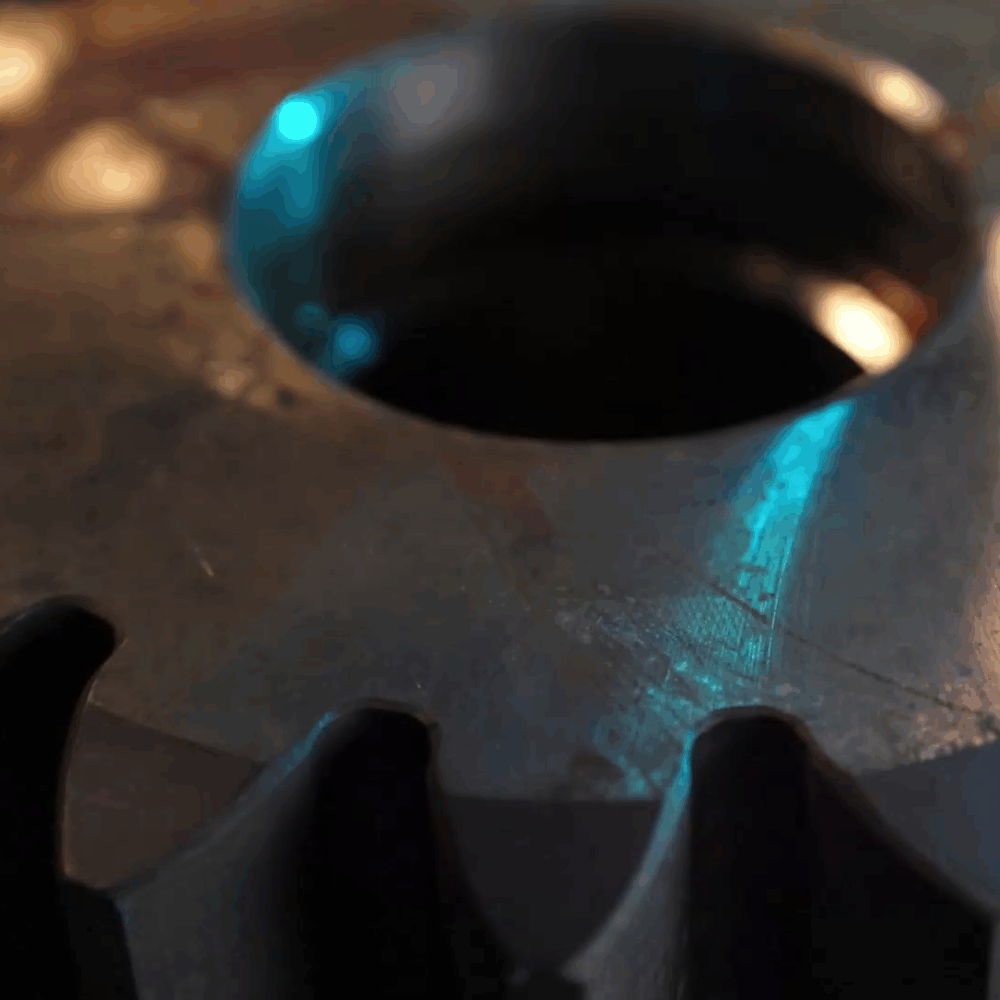

- Precision: Selectively removes contaminants without affecting the base material.

- Eco-friendly: Operates without chemicals or water, reducing environmental impact.

- Versatility: Effective on various materials including metals, stone, and composites.

- Efficiency: Often faster than conventional cleaning methods, improving productivity.

- Safety: Eliminates risks associated with chemical or abrasive cleaning agents.

Test Laser Cleaning on Your Part

Curious how Nuwave’s Laser Cleaning Machines perform on your specific material or contaminant? Send us a piece, and our experts will clean it for you, showing you the precise and elegant results you can expect.

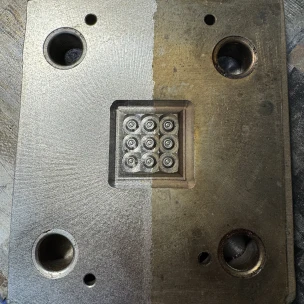

Applications and Use Cases

Learn Where Laser Cleaning Fits in Prep, Restoration, and Maintenance.

Advancing Industrial Cleaning

Laser Cleaning Technology Is Reshaping Industrial Maintenance Practices.

Art & Heritage

Gentle, chemical-free cleaning for sculptures, monuments, and historic facades.

Not Sure Which System You Need?

We’ll help you compare your options and choose the laser cleaning machine that aligns with your workload, materials, and production goals.